KMACH customized one head filling system for Haifeng farm

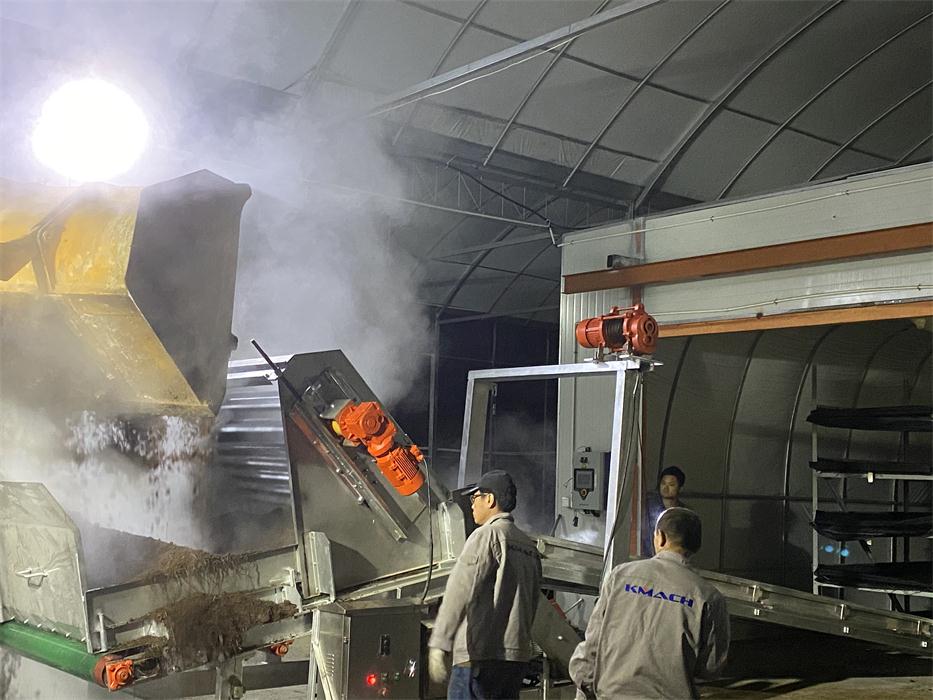

We have customized,manufactured and installed one set of convenient, economical but durable and high-performance simple-version growing room head filling system for Haifeng farm which is a small-scale family farm with 6 growing rooms located in Pinghu city of Zhejiang province. The filling system consists of 1 filling machine and 1 dosing hopper. This farm was filled manually with bulk Phase I compost onto the growing nets laid on the beds and made Phase II compost in the growing room. Each growing room has 3 hot-galvanized growing racks, which are 1.2 meters wide and 25 meters long, 5 beds high.Normally it took around 2 days for 6 to 8 workers to fill a room. After applying the KMACH head filling system, it only takes half day to fill one room.

In China, it is an inevitable and logical trend that more and more small-scale mushroom farms have to apply some composting and growing equipment and machinery to upgrade their production mode in order to survive the harsh competition and also due to the reason that it is more and more difficult to get young workers to handle such hard labour, and labour cost is increasing too much, only middle-aged and old-aged farmers are still willing to work in the traditional and manual mushroom farm.

In order to help such small-scaled farms to continue their business in the right track, KMACH team have spent some months to learn and analyze the factual conditions and worked out the low-cost but very useful composting and growing solutions for them, including growing room filling system, emptying system, small bunkers and tunnels, bunker/tunnel filler, etc.